- Penn state learning factory training full#

- Penn state learning factory training series#

- Penn state learning factory training free#

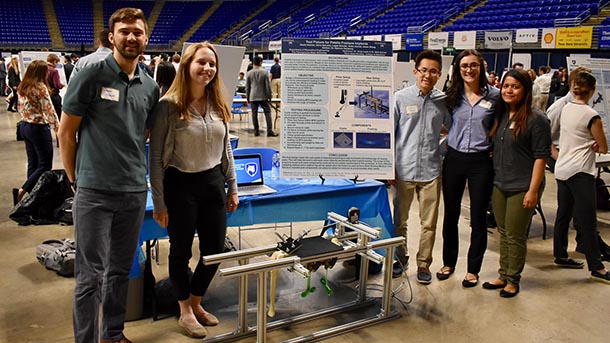

Physical Prototype or On-Campus Equipment: NO Implementing pallet mole system at Lancaster DC Legend: 1 = Primary Discipline | 2 = Secondary Discipline | 3 = Optional Discipline(s) Company Name The staff needs to be fully on board with making safety and a welcoming environment the two most important concerns.Check majors below to filter projects by those majors only: Biomedical Engineering The space was originally viewed as a place for mechanical engineering students, and has since broadened its mission to welcome students from all engineering disciplines and those from outside engineering. We strive to maintain a welcoming environment where students of all experience levels and backgrounds can feel comfortable working and learning. In keeping with our name, the Learning Factory provides students the opportunity gain experience and confidence in using the equipment themselves. The Learning Factory gives students an opportunity to build and implement what they design, which is an invaluable educational experience. Other activities in the facility include design classes, and tours for industry representatives and campus visitors. In addition, student organizations such as the Penn State race team heavily use the facility in building their formula car each year. Students in other design project-based courses such as the junior-level design course in Mechanical Engineering frequently use the facility as well. The everyday users are primarily capstone design students working on prototyping their designs. Additional training in machining and welding is also available every semester for students. At any given time, the space is usually overseen by at least one shop supervisor and two teaching assistants.īasic safety and power tool training is required for all users of the facility.

Penn state learning factory training full#

The Learning Factory staff consists of a faculty member serving as Director, two full time staff members serving as shop supervisors, a full time staff member serving as Program Administrator, and a team of about 12 students serving as teaching assistants. Students must provide a university account number before using these equipment. The waterjet cutter costs $4 per minute for undergraduate course projects and $8/minute for other projects. The 3D printers cost $8/cubic inch of material for undergraduate course projects and $16/cubic inch for other projects.

Penn state learning factory training free#

All other equipment is available to use free of charge. Only the 3D printers and water jet cutter have a cost associated with their use.

Penn state learning factory training series#

Ĕ Bridgeport Series II milling machines with digital readout (DRO).ē axis Bridgeport CNC Machining Center (Torq-Cut V22).Weekend hours are added during the last month of each semester due to the high demand. Penn State students working on class projects, research projects, or student organizations are welcome to use the Learning Factory, provided that they complete the safety training. The facility is supported by the Penn State College of Engineering and gifts from corporate sponsors. Gordon Learning Factory facility was originally built as a prototyping space for capstone design students, and has expanded to serve as a makerspace resource for all Penn State engineering students. The Learning Factory began in 1995 with the aim of bringing the real world into the classroom through practical, hands-on design projects.

0 kommentar(er)

0 kommentar(er)